Heavy equipment is essential to most large industries, including construction, mining, oil and gas, transportation, and manufacturing. These machines are subjected to wear and tear as they have a demanding task to accomplish, enabling us to perform tough jobs under adverse circumstances. Reliable spares are crucial to maintaining the optimal condition of these devices. Partnering with the right heavy equipment parts supplier can make all the difference in a machine’s ability to keep on trucking.

Considering the numerous suppliers in the current market, you should be very selective in finding the right one. Choosing a professional ipecac supplier ensures authentic products, timely delivery, technical support, and long-term trustworthiness. In this article, we will discuss some of the most important criteria you should look for in a heavy equipment spare parts supplier and why your choice makes all the difference.

Downtime of HEMMs is the doom day for my economy. Whether an excavator in a construction site or a bulldozer working on a mining project, any hour of downtime eats both time and money. The quality and availability of parts have the most impact on a machine’s productivity in the field.

With a reliable supplier, you can expect to receive:

- Genuine and durable spare parts

- Compatibility with specific machine models

- Support for urgent requirements

- Reliable warranties and after-sales service

At the same time, purchasing from unproven suppliers exposes you to the risk of counterfeit components, subpar replacements, and uncertain lead times. So it’s not that the cheapest wins — it’s long-term value.

Assessing the Reputation of the Supplier

The basis of trust is the supplier’s reputation. Before dealing with a heavy equipment spare parts supplier, it is essential to know their business history. Find out how long they’ve been in business, what industries they cater to, and what their customers say about them.

Supplier reliability is also often uncovered in customer reviews, testimonials, and case studies. Any industry recognitions or relationships with reputable equipment manufacturers can help to lend credibility. It goes without saying that a good supplier is clear on where and how their parts are sourced, so there’s no need to wonder or second-guess.

NOTE:- Industries had long depended on Heavy equipment spare parts suppliers in UAE to keep projects on track. Sintra was known for delivering high-quality solutions that met global standards. Their dedication to customer satisfaction had been proven time and again. Connect with Sintra now and safeguard your operations with reliable spare parts.

Ensuring the Availability of Genuine Spare Parts

Authenticity of Spares: Authenticity of the spares should be your utmost concern. Large machinery is precisely manufactured, and counterfeit or inferior parts can have a drastic impact on performance and safety. OEM (Original Equipment Manufacturer) fittings are designed to function just as the original part was intended to. Highest quality, genuine OE fit for your machinery, designed for long life and high performance.

Reliable suppliers may take measures to ensure authenticity, such as:

- Work directly with OEMs as partners.

- Supply your own boxes, and serialize the products properly.

- Offer manufacturer-backed warranties

After you verify them, you can prevent further failures due to low-quality replacements.

Evaluating the Range of Spare Parts Offered

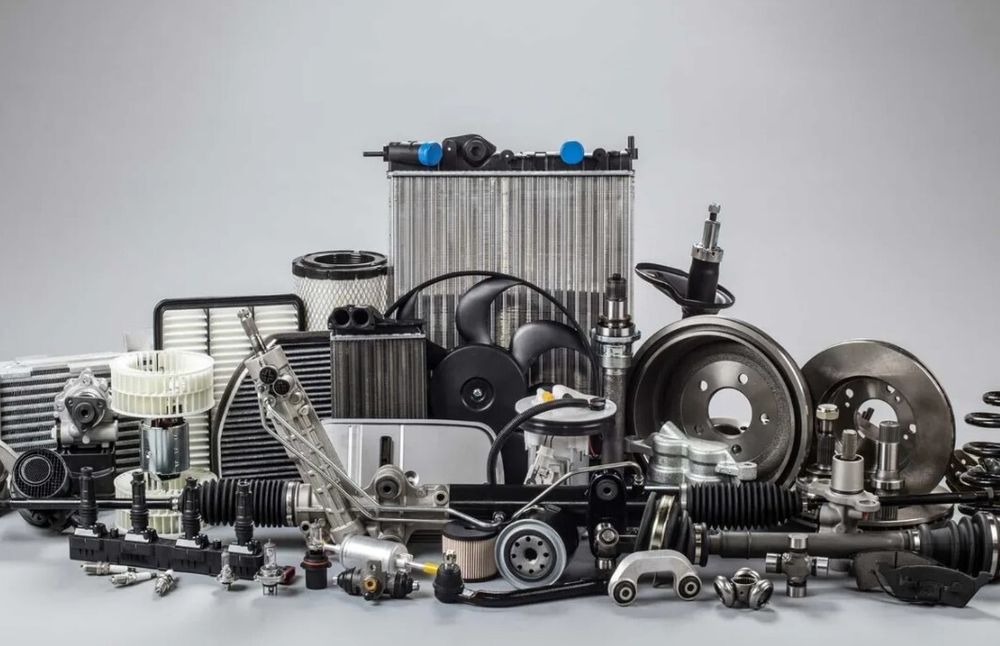

An excellent supplier would be able to offer a comprehensive selection of parts for various types of heavy equipment. This includes components for engines, transmissions, hydraulics, brake systems, filters, and undercarriage. The more variety, the more convenient it is to obtain all your needs from a single source and avoid multiple vendors.

Secondly, vendors who have both OEM parts and premium aftermarket parts available give consumers a choice. Original Equipment Manufacturer (OEM) parts provide peace of mind with perfect compatibility, but at times, aftermarket options can be cost-effective without compromising on performance, provided they come from a trusted source.

Checking for Global and Local Supply Capabilities

In applications with 24-hour operating cycles, the availability of spare parts is highly important. A supplier with a solid network of distributors, either at local or global levels, that will make parts available in a short lead time. For small orders, local suppliers can offer quicker delivery due to the shorter distance, while big orders may refer to global suppliers that have multiple warehouses to manage projects from different locations.

Punctual delivery will reduce downtime, and after-sales logistics support is a key indicator of a professional supplier. Certain top vendors may even offer emergency shipping or hold stock for repeat buyers.

Technical Expertise and Support Services

Heavy equipment spare parts are not only a matter of supply, but also require technical expertise. A reputable source will have professionals who are familiar with the technical details and application of each component. They can advise, recommend, and provide you with installation and maintenance tips if needed.

Many top suppliers also provide:

- On-site technical assistance

- Diagnostic services to identify faults

- Training of machine operators and maintenance. Send your message to this supplier.

The added assistance fosters solid, long-term relationships, resulting in fewer costly mistakes during equipment repair.

Pricing Transparency and Value for Money

Affordability is critical, but affordable does not mean cheap. A Priced Right Supplier targets its competitors while it guarantees open quotes. Obscure billing or extra charges can sow arguments and lost dollars.

“Value for money means that price, quality, and service are balanced.” Dedicated providers guide you through the differences between OEM and aftermarket, while also helping you determine which one is ideal for your budget and operations. Bulk order incentives, loyalty perks, and payment flexibility can also provide value to ongoing customers.

Warranty and Return Policies

A warranty is a representation of the supplier’s confidence in their goods. A good company offers a warranty against manufacturer’s defects and against early failure. There might be different warranties covering OEM parts and aftermarket parts, but the duration of each should be clearly established.

Returns and Replacements are also important. If defective parts are received or the wrong parts are shipped, there should be a straightforward procedure to resolve the issues as quickly as necessary. Transparent warranties and return policies promote greater trust, and you build strong customer satisfaction.

After-Sales Service and Long-Term Partnership

A good after-sales support system is a key indicator of a serious spare part supplier. Professional suppliers care more than just selling parts – they want to develop long-term relationships. They offer post-purchase support, inventory tracking, and occasional visits to ensure everything is running smoothly.

A seller who holds themselves accountable beyond the point of sale shows they are invested in your success. It is this relationship-driven service that serves as a lifeline to companies where constant machine utilization is required.

Technological Integration and Modern Solutions

Today, process engineering equipment manufacturers utilize technology to automate processes and increase productivity. Customer viewing features, such as online parts catalogs, Real-Time Inventory Look-Up, and Digital Tracking Components, help make customer shopping for parts quick and easy.

Some vendors also offer mobile apps or Web portals through which customers can:

- The search for parts by equipment serial number 92C533RD093 can be found in the following Exploded View

- Check availability instantly

- Track delivery in real-time

This electronic benefit not only saves time but also ensures greater accuracy in ordering and supply.

Evaluating Supplier’s Compliance with Safety and Standards

Heavy equipment is associated with numerous safety risks. Therefore, it is crucial that replacement parts vendors adhere to international safety and quality control standards. Certifications, such as ISO, or adherence to industry standards, can indicate that a supplier is committed to quality and safety.

Suppliers that arbitrarily disregard these criteria do not deliver high-quality parts that satisfy performance/ and worker protection. Before entering into any partnership, ensure that the provider complies with applicable industry standards.

Building Trust Through Communication and Responsiveness

Effective communication is an essential aspect in determining the ideal supplier. Prompt replies to inquiries and questions, clear descriptions of products, and the provision of online assistance all indicate professionalism.

Suppliers that frequently communicate during the purchasing and delivery process help lower uncertainty and build trust. A worthy supplier indicates that they understand the customer is more important than a quick buck.

Conclusion

Opting for the right heavy equipment spare parts supplier is a strategic move that affects efficiency on site, the longevity of the machine, and overall profitability. A good supplier does products, technical advice, logistics, pricing, and ongoing support. In addition to parts, they are loyal partners with you at the heart of your business.

In view of the increasing trend of updating and upgrading, a professional supplier of spare parts will become even more important in the future. Businesses can confidently evaluate suppliers that meet their needs in terms of reputation, authenticity, availability, service quality, and compliance.

When it comes down to it, a reliable vendor is more than just the company you buy from, they are part of your operation that keeps things moving in top shape while minimizing downtime and interruptions.

For more insightful articles related to this topic, feel free to visit – findtopbusinesses